Bottle pouring sterilizer:

It is mainly used to sterilize the bottle mouth and the inner wall of the bottle cap without sterilization or high temperature treatment after hot filling of juice and tea drinks packaged in PET polyester bottles.

Workflow:

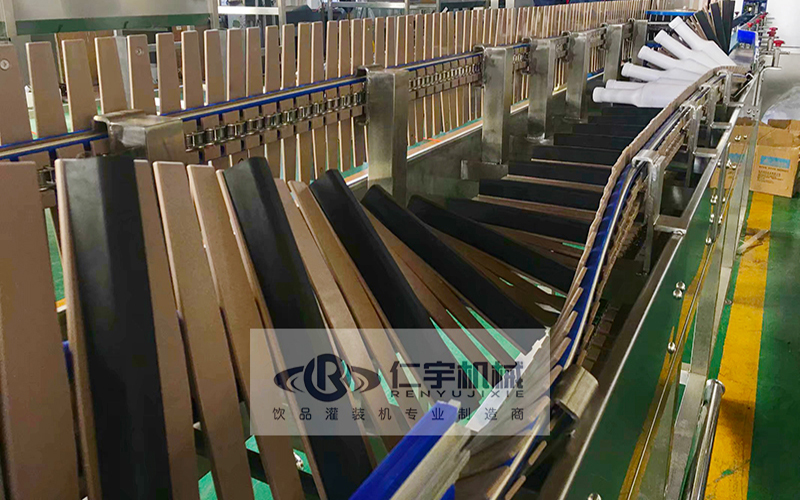

The bottle pouring sterilizer is mainly composed of a transmission chain system, a bottle body reversing chain system, a rack, a bottle turnover guide rod, etc.: the machine realizes automatic turnover sterilization and self reset, and in the sterilization process, it only needs to sterilize the bottle mouth and the inner wall of the bottle cap through the self high temperature of the contents in the bottle, without adding any heat source, so as to achieve the purpose of energy conservation.

Main purpose and scope of application:

The bottle pouring sterilizer is mainly used to sterilize the gap between the bottle mouth and the bottle cap that cannot be touched by high-temperature materials after hot filling and capping of tea and fruit juice drinks. After filling and capping, the machine will automatically turn the bottle 90 °, sterilize the inner wall of the bottle cap through the material temperature, and then enter the spray cooler. The automatic bottle pouring and sterilization conveyor is stable and reliable, without damage to the bottle body, and the transmission speed is stepless.

Product features:

1. The machine is made of SUS304 stainless steel, with simple structure, beautiful appearance and convenient operation.

2. The length of the bottle pouring sterilization system is calculated according to the filling output required by the customer per hour. The sterilization time is 15-40 seconds for the user to choose, and the speed of the transmission chain can be adjusted.

3. The bottle pouring sterilization system is generally used together with the spray cooling equipment afterwards. After bottle pouring sterilization, the spray cooling equipment is connected through the conveyor belt to spray the bottles for cooling, completing the whole sterilization cooling process and ensuring the fruit juice filling effect.

4. The bottle inversion sterilization system mainly completes the whole process through the transmission chain system, bottle inversion chain system, rack, and bottle inversion rod, without any pollution to the bottles. Frequency conversion control, adjustable transmission chain speed, and the whole process is safe and reliable.

5. The machine adopts imported transmission chain, which is driven synchronously by double chains. The chain is stainless steel plastic steel torsion chain. The surface of the large chain is equipped with a temperature resistant rubber head, which keeps rotating mutually, stable and reliable. The bottle body is not damaged, and the transmission speed can be adjusted steplessly.

6. The bottle reversal sterilization system realizes automatic reversal sterilization and self reset. The filled beverage is automatically inverted by 90 degrees. The bottle cap and inner wall are sterilized again using the high temperature of the canned beverage itself. After that, the bottle is automatically placed in the right direction. It is unnecessary to add any heat source to achieve the purpose of energy conservation.

Generally, acidic tea lasts for more than 45 seconds. Neutral tea lasts for 90-120 seconds, and medium temperature filled tea (filled at about 90 ℃) lasts for about 7 minutes.

Applicable products: fruit juice, tea drinks, functional drinks, milk drinks

Filling method: non-contact filling

Applicable container: 250ml-2500ml PET bottle

Production capacity: 24000-36000 bottles/hour;

Sterilization time: 15-40 seconds for users to choose.

Spray cooler:

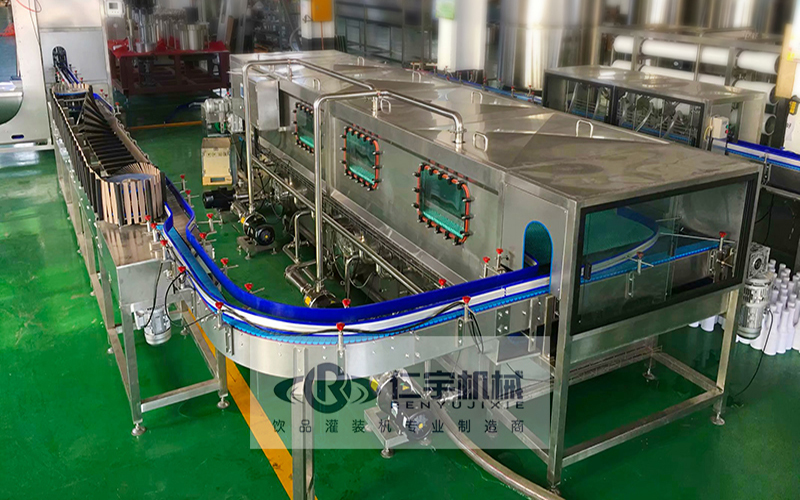

The equipment adopts three-stage treatment or multi-stage treatment of circulating hot water spraying sterilization, warm water pre cooling and cold water cooling. The sterilization and cooling time are variable frequency speed regulation according to user requirements, and the automatic control is highly automatic. It can be used for normal pressure pasteurization of various bottled and canned drinks, canned fruits and vegetables, cooling of PET filled tea drinks, and warming of aerated drinks.

Product features:

1. High temperature resistant polypropylene (HTPP) chain plate is used, and Japanese electrical components are used. The body is made of stainless steel, which is stable and reliable in operation, compact in overall structure, and sanitary and beautiful in appearance.;

2. High quality plastic mesh belt chain plate can work under high temperature (≯ 98) for a long time and 104 ℃ for a short time;

3. Solid conical wide angle nozzle, uniform and stable flow distribution, constant temperature field;

4. Comprehensive utilization of various energy and heat recovery technologies, energy conservation and environmental protection;

5. Temperature sensor Pt100, high measurement accuracy, up to ± 0.5 ℃;

6. Multi process combination, reasonable process, can handle a variety of materials;

7. The sterilization temperature is controlled by PLC touch screen.

8. Frequency conversion control of total processing time can be adjusted according to the production process;

9. For PP bottles, plastic bags, roof cartons, glass bottles, cans and other products with non-circular packaging, automatic feeding and unloading mechanisms are configured, and the connection with the automatic conveying production line is smooth;

10. It can provide users with heat distribution testing services, and use the expert system to monitor the temperature change in the whole production process online.

11. With automatic control of sterilization temperature and stepless adjustment of sterilization time:

12. It can be widely used for sterilization and cooling of various bottled and canned acidic juice drinks, electrolyte drinks, wines, condiments and other products;

13. The equipment can be designed according to the sterilization conditions and output requirements proposed by users.