summary:

3L-15L large bottle water filling machine realizes three processes of bottle flushing, filling and capping on one machine, which shortens the contact time between materials and the outside world and improves the sanitary conditions. The hanging type bottle mouth conveying bottle structure makes it easier to change the bottle type It is fast and labor-saving. The host machine adopts advanced PLC programmable automatic control technology, and the key electrical components are products of internationally famous commodities.

Scope of application: It is applicable to the filling and production of pure water, mineral water, mountain spring water, natural water and other non bottled water packaged in PET bottles.

The plastic bottles have the same mouth, and the bottles with different diameters can be shared! Only the relevant accessories need to be replaced.

The output can be selected from 400-3000 bottles per hour!

Product features:

1. The bottle inlet air duct adopts the way of hanging the bottle neck, and the bottle feeding speed is fast and the bottle will not be deformed.

2. The applicable bottle type of each part can be adjusted easily and quickly.

3. The touch screen designed with humanized concept is extremely convenient for operation and can realize man-machine conversation operation.

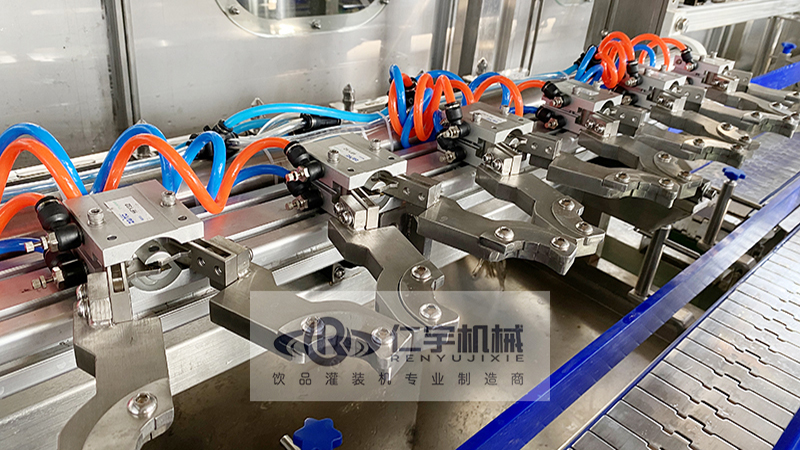

4. In addition to the rack, the whole machine is made of high-quality stainless steel, which is stable in operation, free from vibration, dead angle in process and easy to clean.

5. The specially made high speed filling valve ensures accurate liquid level without liquid loss and realizes no filling without bottle.

6. The programmable logic controller (PLC) realizes the automatic control of the whole production process, which is easy to operate and highly automatic.

7. The man-machine control system can realize the functions of detection of missing cap, production speed control, output counting and automatic stop of bottle jamming.

8. The perfect overload protection device can effectively protect the safety of operators and equipment.

9. The capping head device with constant magnetic torque is adopted to ensure the capping quality without damaging the bottle cap.

10. It adopts an efficient cover management system with perfect automatic control and protection devices.

Production line process:

Water treatment system → bottle blowing machine → bottle feeding and conveying → three in one filling machine (bottle washing, filling, sealing, automatic capping and online cap disinfection) → conveying → light inspection box → drying machine → automatic shrink labeling machine (labeling machine) → film packaging machine (packing machine) → stacking machine → finished products.

Product model | rinse | filling | seal | Rated output (10L) | Power KW | Equipment dimensions | remarks |

CGF4-4-1 | 4 | 4 | 1 | 400BPH | 3.68 | 3600*1500*1850mm | Linear |

CGF6-6-1 | 6 | 6 | 1 | 600BPH | 4 | 5000*1500*1850mm | Linear |

CGF8-8-1 | 8 | 8 | 1 | 800BPH | 4.5 | 6000*1500*1850mm | Linear |

CGF9-9-4 | 9 | 9 | 4 | 1000BPH | 6.5 | 3600*2400*2500mm | Rotary |

CGF18-18-5 | 18 | 18 | 5 | 1800BPH | 15 | 7300*3000*2500mm | Rotary |

CGF24-24-5 | 24 | 24 | 5 | 2500BPH | 20 | 8500*3800*2500mm | Rotary |

CGF32-32-6 | 32 | 32 | 6 | 3500BPH | 24 | 9000*4000*2500mm | Rotary |